The bead factories, situated where the 8th street of the commercial area and the 5th street of the residential area meet, comprised the main industry of the Harappans. They probably settled (or their culture came) to the Gulf of Cambay region because of its agate and precious stone resources.

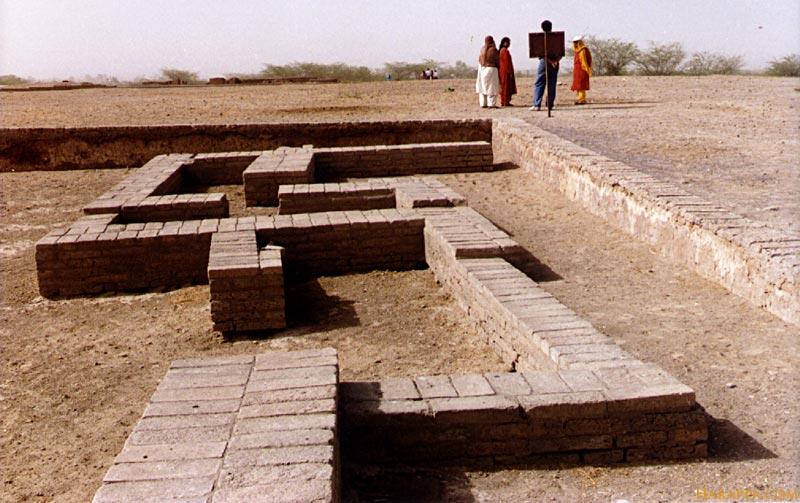

The factory comprised 11 rooms, which included worker's quarters, warheouses and guard rooms, surrounding a courtyard. The main bead making machine was a twisted chambered kiln, made from mud plastered bricks, which was used for heating the stones used to make beads. Bellows helped raise the temperatures within.

Lothal was especially famous for its micro-beads. These were made by grinding materials, rolling them on to a string, baking it solid. Finally the baked roll was sawed into required shapes and sizes.

Unique necklaces were made with microbeads of gold. Some were as little as 0.25mm in diameter. They are testimony to the science of beadmaking perfected by the Indus Valley civilization, and has not been surpassed by artisans in the Gulf of Cambay today.

The middle classes who could not afford gold contented themselves with gilded copper wires. Low income groups must have worn ornaments from shells and clay. Coppersmithing and pottery reached high standards of development in the lower town.